Overview

Will update with more information shortly. Thanks!

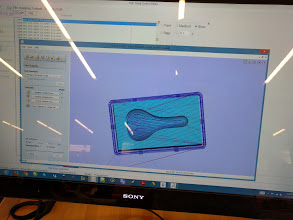

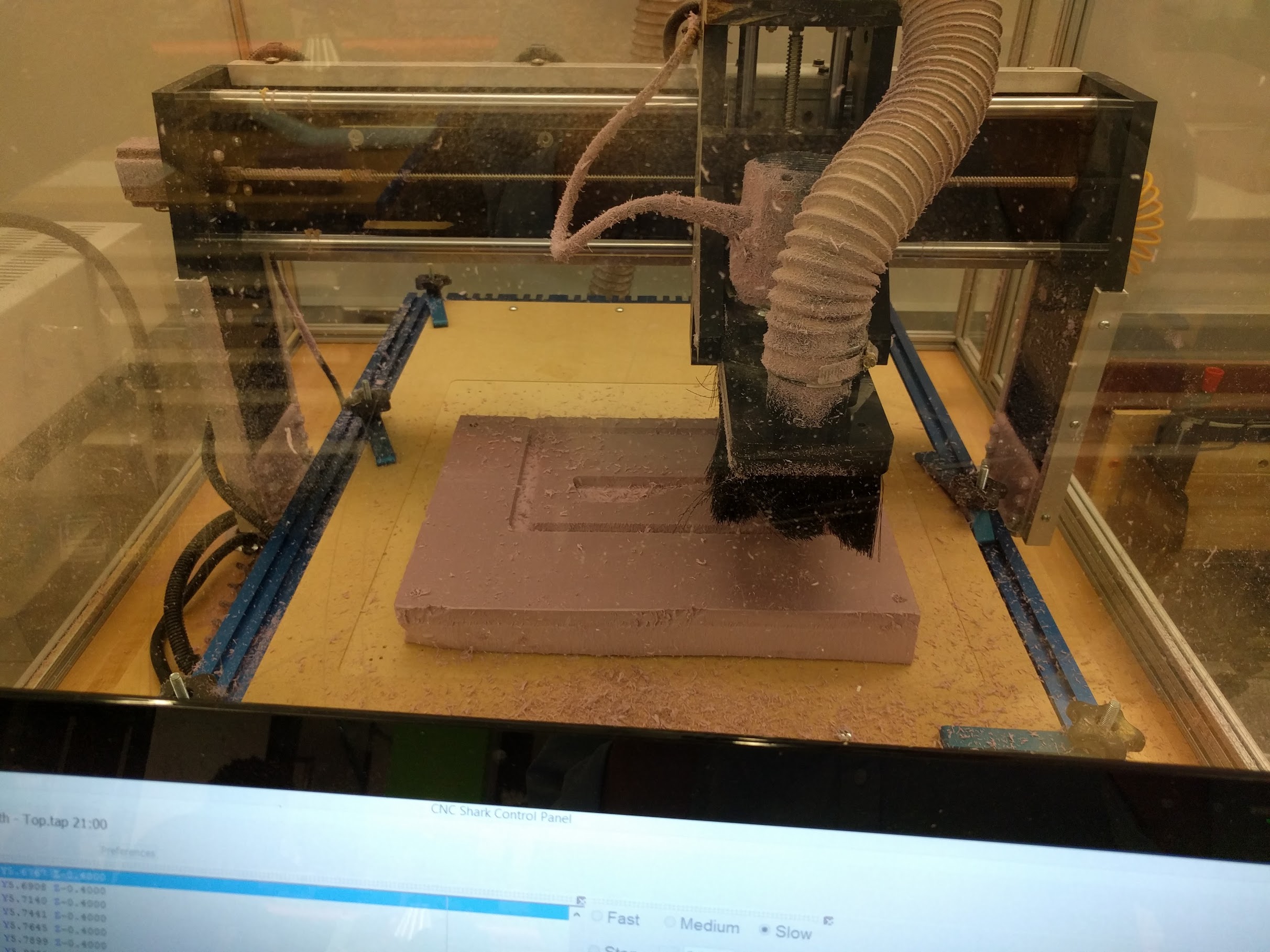

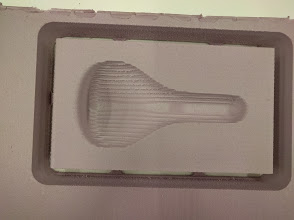

Below you will see some photos of the process. The bike seat was modeled in Solidworks, then a mold was modeled using Solidworks Mold software, then exported to a custom cam package that the class used and gcode was exported from there. The mold was then machined into a chunk of foam using a small Shopbot.

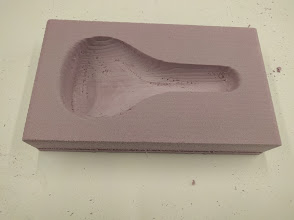

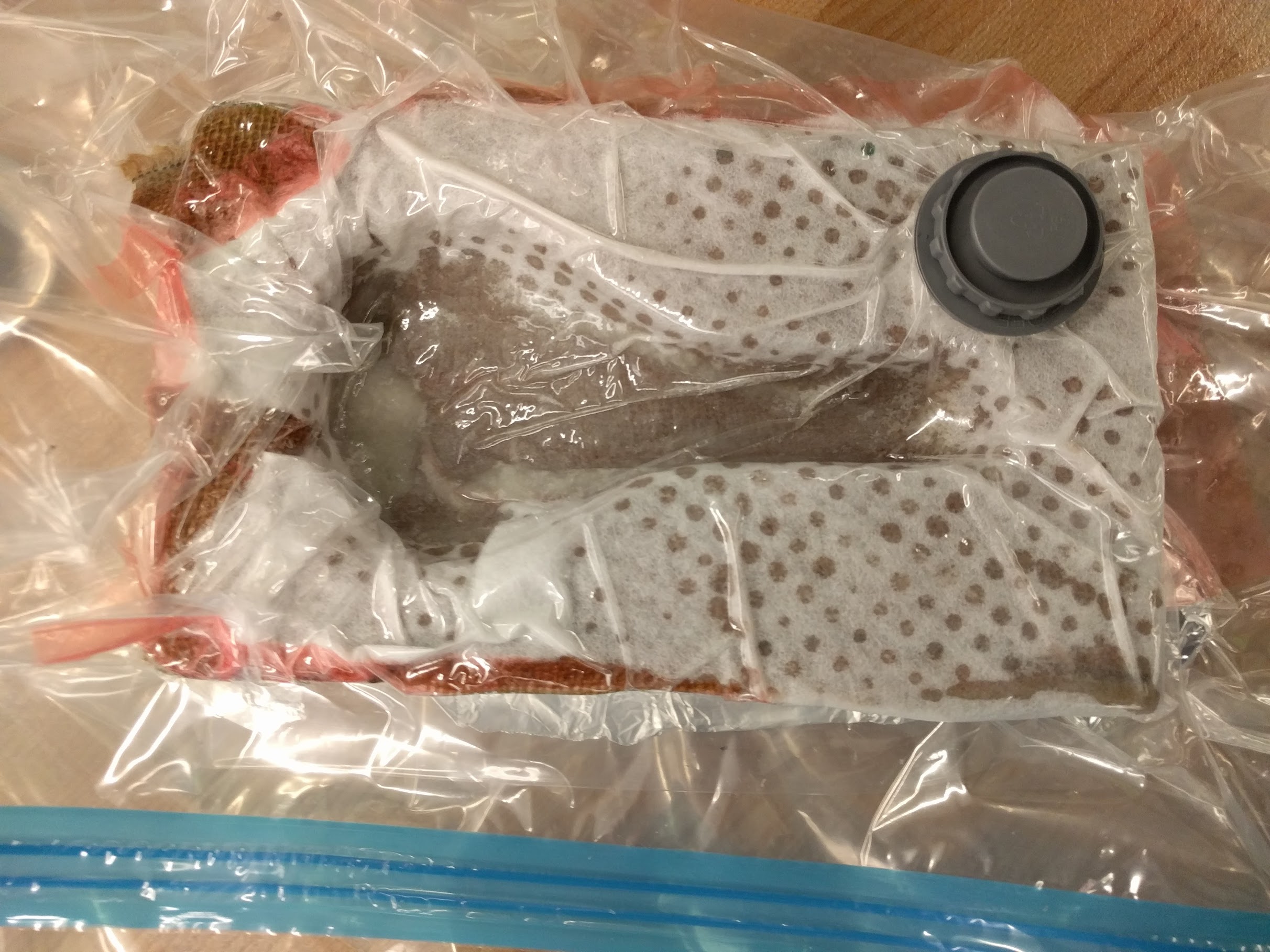

The mold was then carefully sanded down to make smooth. Burlap sheets were cut out to match the size and layout of the mold, then spread with epoxy, and laid into the mold along with the bleeder cloth, breather cloth, and vacuum bag. It was then held at vacuum for 12 hours to cure.