Welcome

My name is Samuel Belden, and I am a Materials Engineer at SpaceX working on providing high speed, low latency internet to the world with Starlink. I graduated from MIT in 2018 with a Bachelor's Degree in

Materials Science and Engineering.

I'm primarily interested in mechanical design, polymer science, and electrochemistry. My focus in industry so far has been in product design, adhesives and polymers design/testing/selection, process engineering, materials reliability/accelerated testing, and in bringing up mass production consumer electronics. I was involved in various materials science projects and research in my time at MIT, ranging from lab work to hands-on prototyping and manufacturing.

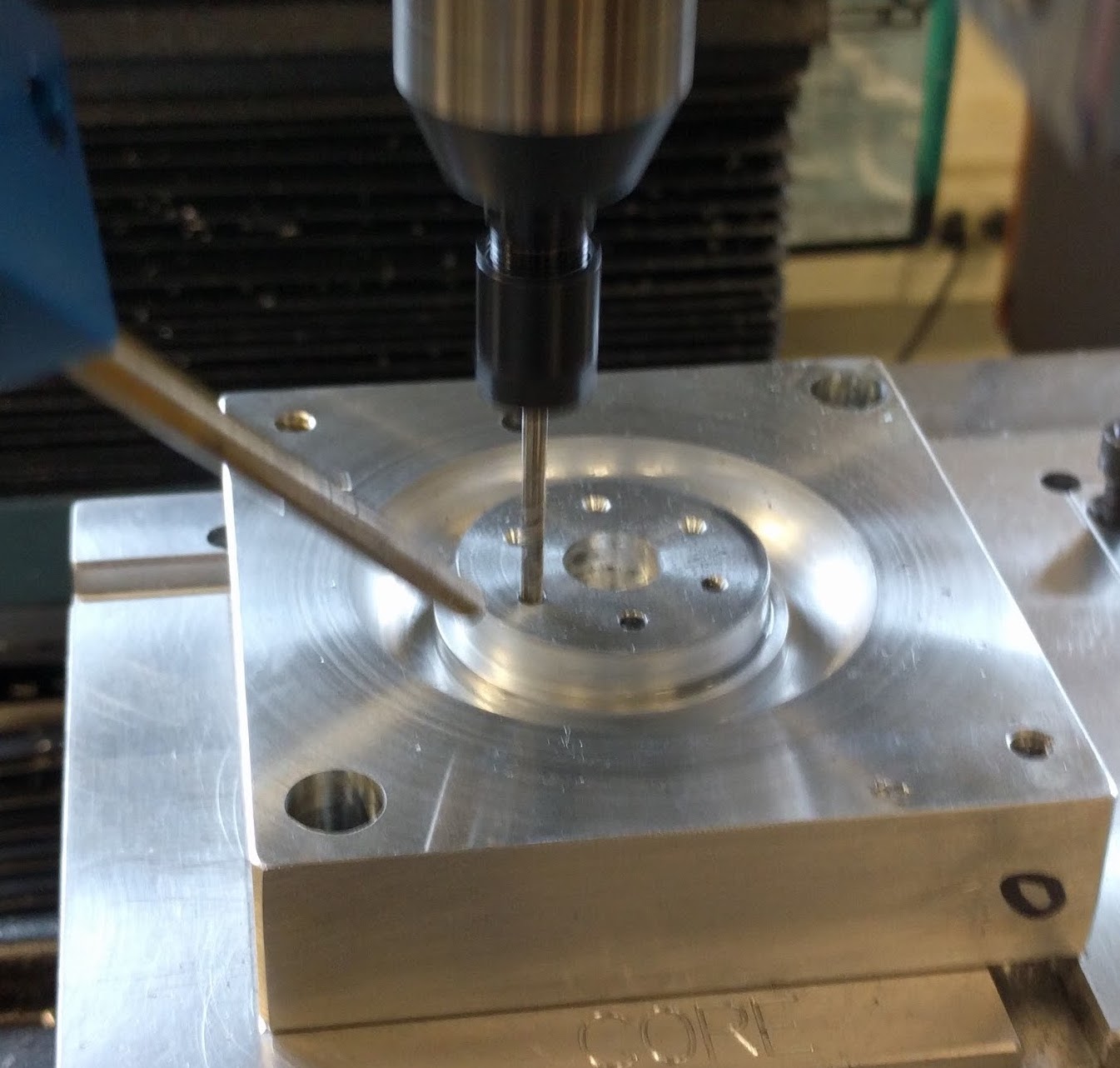

I enjoy hands-on, challenging engineering projects. I've built my own electron microscope that can 'see' atoms, made custom injection molded yo-yo's, designed and built my own carbon fiber bike, and built a variety of 3D printers/cnc machines, along with various other projects. I always have a few projects in the works!

Outside of work, I'm an

avid backpacker, camper, hiker, rock climber, canoer, rower,

cook, baker, and entrepreneur.

Research Focus

- Mechanics of Materials

- Composites

- Polymers and Adhesives

- Mechanical Design

- Additive Manufacturing

- Electrochemistry

- Process Engineering

Industry Experience

- SpaceX - Lead Starlink Engineer (pcbs)

- Apple - iPhone Product Design Intern

- CEiiA (Portuguese Aero Company) - Intern

- Research in EEL Lab

- Research in Grossman Lab

Other Interests

- Camping/Backpacking/Canoeing

- Cooking/Baking

- Travel

- Rock Climbing

- Consumer Technology

While at Apple, I worked primarily on both the AirPower wireless charging mat and the next generation iPhone 8 and 8+. I designed and fabricated several test setups through collaboration with electrical engineering, materials, and product design teams for benchmarking technologies and conducting user experience studies. I extensively used NX CAD, ANSYS mechanical, thermal, and electromagnetic simulation software, and Matlab.

At CEiiA, I performed market analysis and research on battery managment system (BMS) options for a large 30kg UAV. I designed multiple BMS options in Eagle and had them manufactured and tested. I also performed several carbon fiber layups for another intern's 3-axis gimal design.

Skills - Computer

- Siemens NX and Teamcenter

- Solidworks

- ANSYS (Mechanical, Thermal, Electromagnetic)

- Mastercam

- PCB Design Software (Altium and Eagle)

- Matlab

- Autodesk Revit & Bluebeam

Skills - Tools

- Mechanical Testing - Instron

- Characterization (FTIR, TGA, DMA/TMA, XRD, SEM/EDS, DSC, STM)

- Subtractive (Mill, Lathe, Laser Cutter, Waterjet)

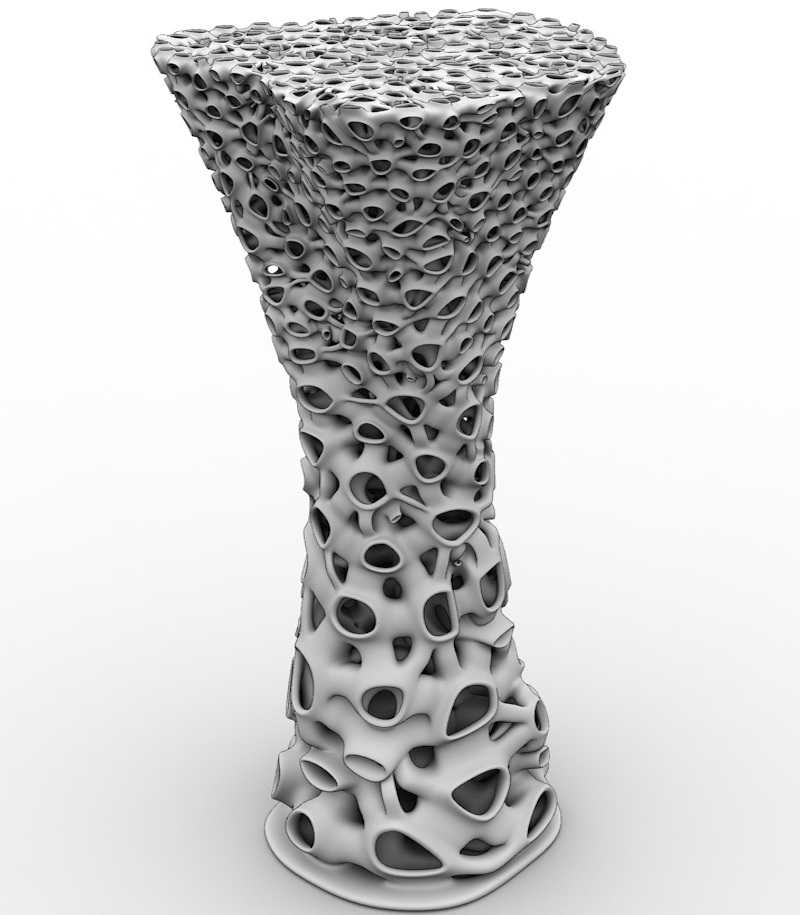

- Additive (FDM, SLA, SLS, Flexo/Gravure/Screen Printing)

- Composite Design and Layup

Skills - Electrical

- PCB Design and Fabrication

- Soldering

- Arduino

- Oscilliscope

- Sensors

Practical experience in

Composite Design and Layup

Have designed and laid up various projects in carbon fiber, fiberglass, and burlap - including motorcycle and racecar fairings, gimbal housings, bike frames and seats, and more

Product Design

Proficient in NX, Solidworks, Rhino, various FEA softwares, ANSYS Mechanical, Thermal, and Electromagnetic packages, Eagle, Matlab, and others. Interned on Apple iPhone Product Design Team

Please email me for the most recent copy of my resume or if you have any questions. Thanks for looking!